Read about the DV1R18 Drainvac Central Vacuum Unit

The DV1R18 is designed as a power force for commercial applications. This is a powerful dual motor system with 790 air-watts (suction power) and an impressive 180” water lift. At only 72 decibels due to its insulated motor housing, this unit is known to be more acoustically sound than most commercial vacuums.

This Drainvac DV1R18 is a cyclonic (bagless) unit. This DV1R18 is perfect for commercial and industrial facilities with a lot of dust, as it can cover large surface areas. The DV1R18 has many filtration methods available and outside vented is recommended for optimum filtration. The DV1R18 comes with a large 12 gallon dirt capacity for less often dirt disposal making the Drainvac DV1R18 perfect for busy industries with industrial sized cleaning. It’s powerful, versatile and reliable offering years of hassle free maintenance.

DrainVac Wet/Dry Advantages

- Strong suction guaranteed

- Has rustproof polyethylene interior

- Corrosion-free

- No bag or filter required.

Warning: Never vacuum flammable matters, gaseous or liquid, with your DrainVac system. See the user manual. All these units require an outdoor exhaust vent. Available with float for wet cleaning.

IDEAL FOR: SMALL, MEDIUM & LARGE HOMES, RESTAURANTS,

AUTO DETAILERS, DOCTORS OFFICE, DENTAL OFFICE, DAY CARE, VET CLINICS AND MUCH MORE!

Features & Benefits of the DV1R18

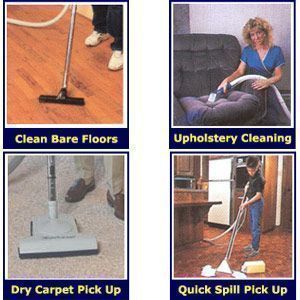

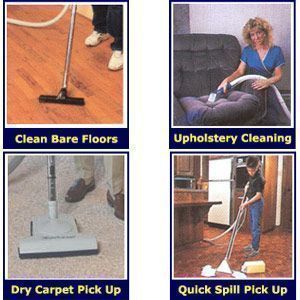

- Wet and Dry Cleaning

- Ideal For Carpets, Furniture, Floors, Mattresses,

Car Interiors & More

- No Post-Cleaning Maintenance

- No Need To Wash The Tank

- Heavy Duty Domel Motor For Superior Suction - Quiet Operation

- Rust & Corrosion Proof Components

- Nothing To Empty, No Bags or Filters

Wet / Dry Systems - Will They Clog?

Anyone who has been in the central vacuum industry for a period of time has run into the problem of clogged vacuum piping from picking up water. In most cases, the cause of this is when the owner accidentally, or sometimes intentionally sucks up moisture into their dry only central vacuum, leaving the vacuum piping and even sometimes the power unit damp. This is then soon followed by vacuuming dry soils which stick to the inside of the piping and begin a build up of debris, eventually causing the clog.

Water itself, is a good cleaner and can be used to rinse out and clean in-wall vacuum lines - if the water has a place to go. When water is under negative pressure being sucked through a vacuum line it travels in a cyclonic action along the inside walls of the vacuum piping, washing them clean as it goes. This is the reason wet/dry systems do not have clogging problems. Every time an owner of a wet/dry system uses it to clean the tile , linoleum, concrete or wood with the brush and squeegee tool, or uses hot water extraction to clean carpets, they're cleaning the vacuum piping as well. The more water being used, the cleaner the pipes will be.

If a customer has gone a while without using the wet cleaning option some debris may be sticking to the piping walls. In this case the customers are encouraged to suck a gallon or two of hot water through the system, which again washes out the piping. Since everything a customer sucks off the floor goes down the drain, they can even clean up pet accidents, throw-up, etc. After these types of clean-ups a customer would add some disinfectant or a cap-full of chlorine bleach to a gallon of water before sucking it through the system, this sanitizes hoses, in-wall piping, and the power unit.

Another important feature of the wet/dry system is power unit design and construction. Water filtration for dust and particles, corrosion resistant materials, automatic shut off and dumping features, with a debris screen are all critical to performance and dependability. Because the power units are designed and capable of receiving both dirt and water, clogging is not a problem. All recovered soil and water is automatically sent down the drain, so both vacuum piping and power unit are always washed clean.

Log In

Create New Account